Responsibility at the Heart of Craft

Sustainability is not a department for us — it is a way of thinking that shapes every decision we make. From the energy that powers our looms to the dyes that colour our rugs, we consider the impact of each step on people, communities, and the planet. We believe that when craftsmanship is paired with responsibility, the result is a product that lasts for generations without costing the earth.

SUSTAINABLE MANUFACTURING

- Solar power panels at our main factory meet 30% of our energy requirement.This equates to approximately 1807790 lbs of CO2 emissions and a saving of approximately 37,666 trees per year.

- At our dye plant, we use locally sourced rice husks instead of coal to generate steam. This has reduced our carbon footprint by approximately 74,000 trees per year.

- We recycle plastic bottles to make PET yarns.These yarns are durable and resilient to changes in weather.On average, we use 5,40,000 bottles to produce 6000 kg of PET yarn per month.

- Reducing the number of steps in our manufacturing process, and keeping the raw materials close to their natural form, helps in minimising waste.

- We use natural hand-spun wool unwoven hand-spun linen. BCI cotton, organic cotton, recycled cotton, hemp, and jute.

- As part of our design process, we are using dyes derived from natural sources, such as indigo for blue, and saffron for yellow. walnut shells for brown. we ve also incorporated azo-free dyes for some collections.

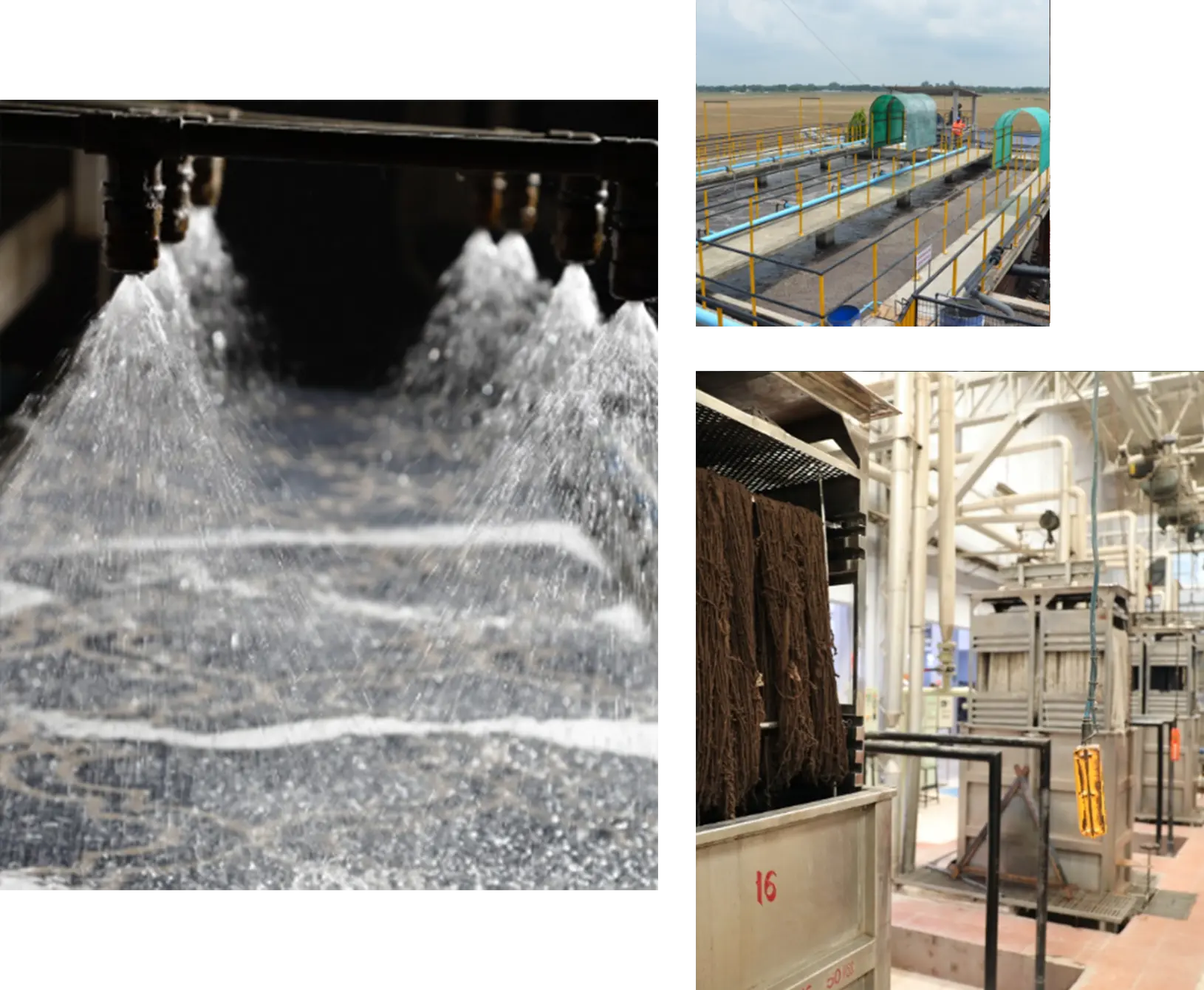

Through water conservation initiatives, we have reduced consumption by 90%.

WATER CONSERVATION

- Typically, washing a carpet uses 30 buckets per square yard. To aid our conservation efforts, we wash our tufted collections with a low concentration of detergent and less water.

- We treat all residual water using our onsite effluent treatment* and wastewater recycling facility. We use this clean water for irrigating the fields around the factory.

- We reuse heated water for dyeing the yarns.

Effluent Treatment Process

The importance in environmental safeguarding. Elaborate on how the effluent treatment process functions to eliminate contaminants from wastewater in a controlled environment.

Channeling

Initial Collection

Primary Treatment

Physical Separation

Secondary Treatment

Biological Process

Tertiary Treatment

Final Polishing

Channeling

The foundation of effective water treatment

Water used to dye and wash carpets is directed to the water effluent treatment plant through planned drainage systems. The treatment plant ensures that the water is properly treated before being released back into the environment.

Primary Treatment

Physical separation and solid removal

Water is treated with alum and lime to clean the effluents. The combination of alum and lime effectively neutralizes harmful substances in the water, promoting better overall water health.

Secondary Treatment

Biological breakdown of organic matter

The water is then treated with live bacteria that are cultivated in-house to clear the water of any organic waste. Through our unique in-house cultivation process, we ensure that only the most effective live bacteria are used to clear the water of any organic waste.

Tertiary Treatment

Advanced purification and disinfection

After going through the biological treatment, the water is filtered through the sand and carbon filters. The water is then released outside and is fit for irrigation. The filtration process ensures that any remaining impurities are effectively removed from the water, leaving it suitable for irrigation purposes.

Our carpets last generations & our practices ensure that the environment does too.

Our Certifications

Fairtrade

Woolmark

RWS

Fernmark

Goodweave

GRS & RCS

SA 8000:2014

Fairtrade

Woolmark

RWS

Fernmark

Goodweave

GRS & RCS